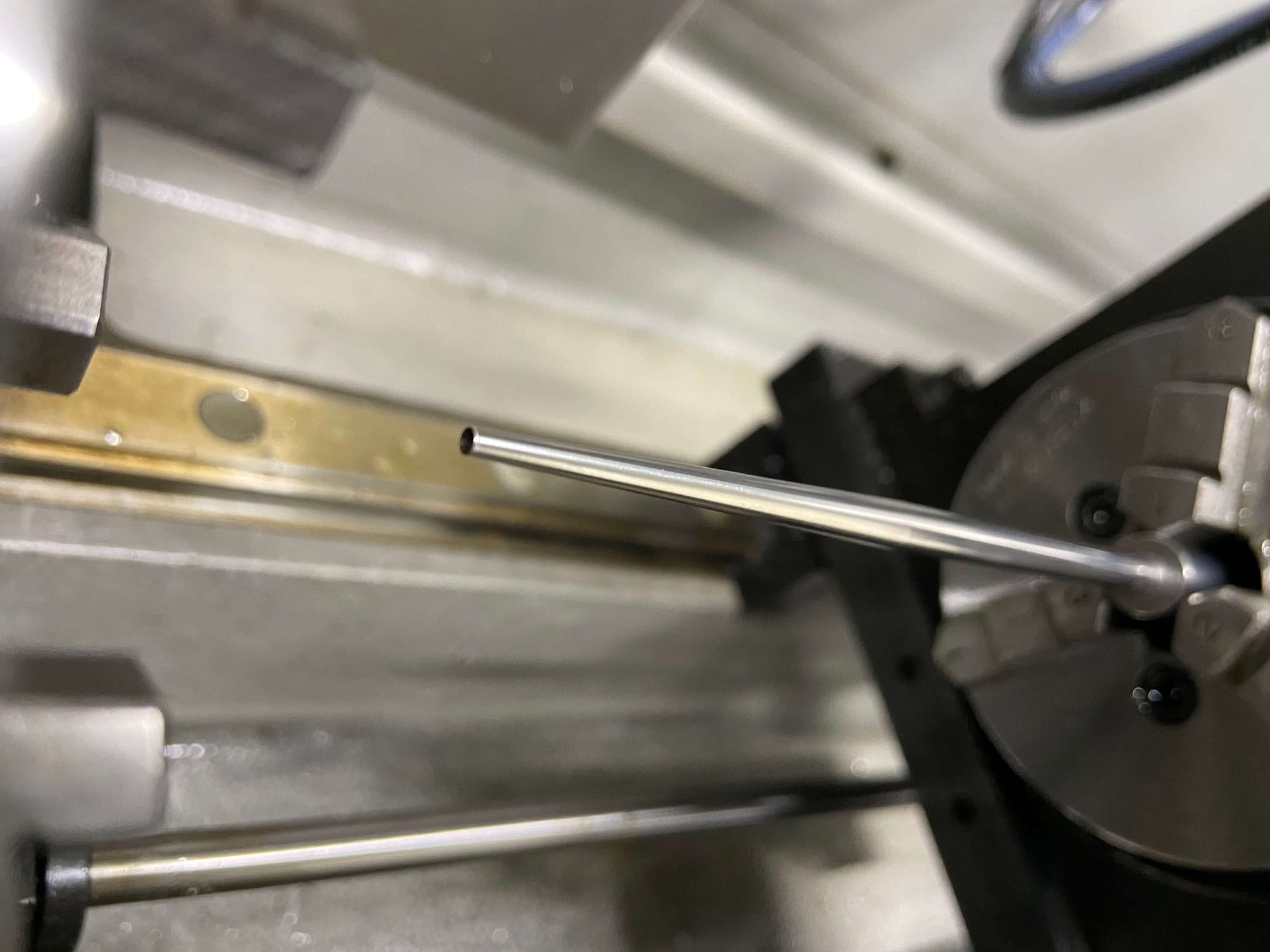

Introducing the world’s first φ1.0mm L/D=400 deep hole boring machine, revolutionizing the industry with small-diameter deep hole drilling technology.

Contents

Description

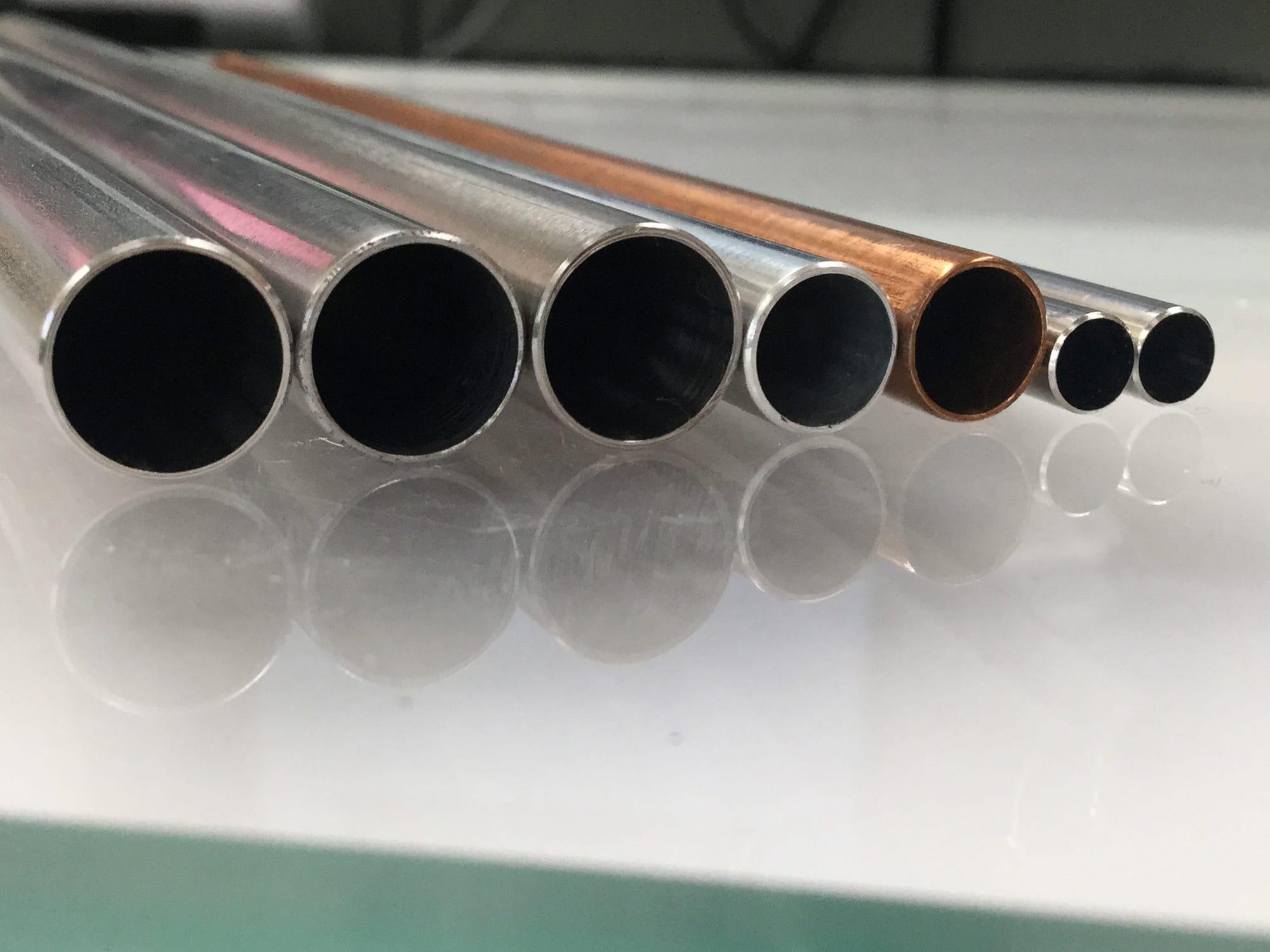

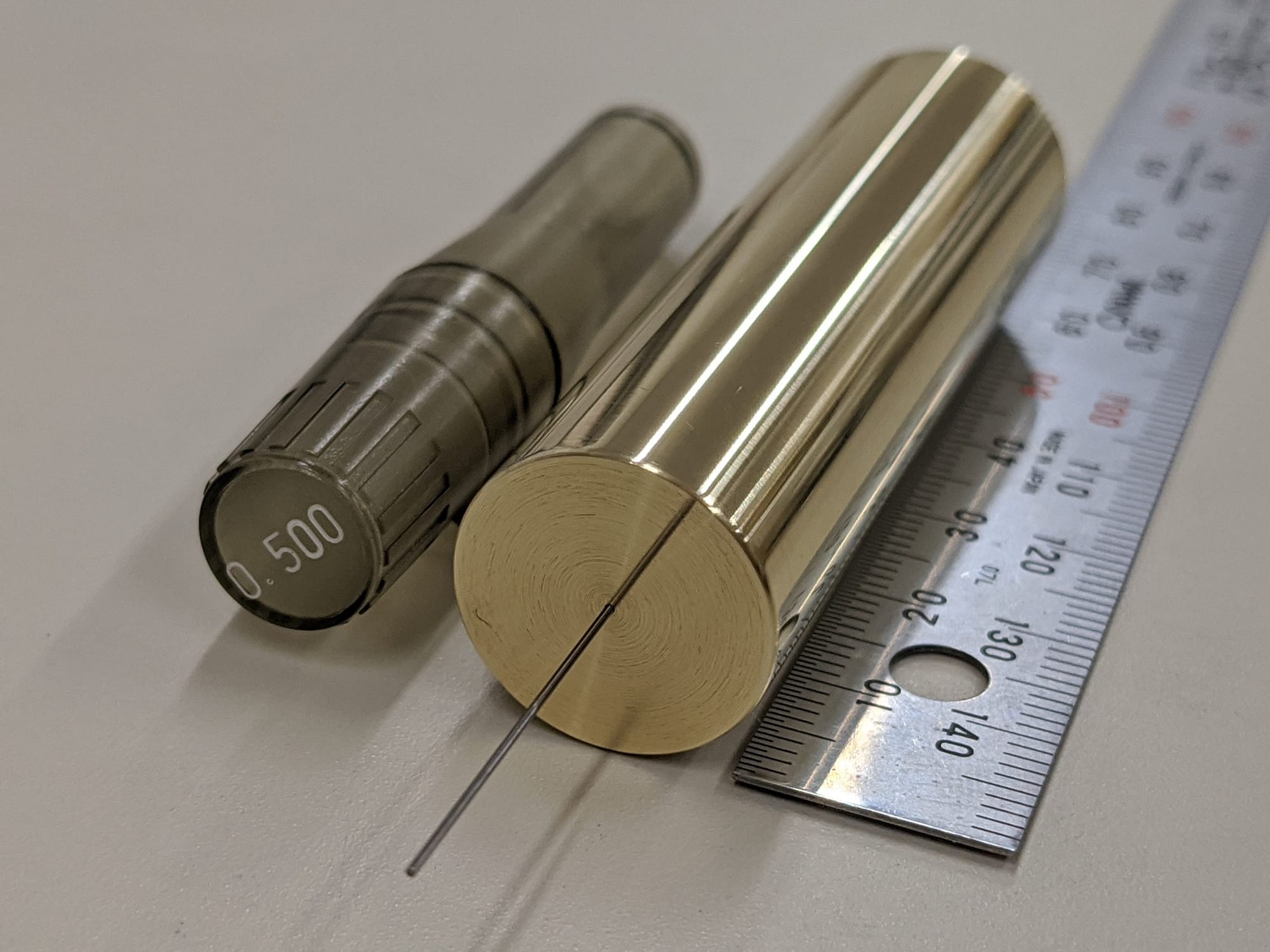

Our gun drilling machines cater to diverse industries, such as medical, aerospace, automobile, and semiconductor, and are equipped to handle challenging drilling tasks, especially for workpieces with small diameters and high L/D. Our models offer high coaxially in deep hole drilling and range from φ1.0 to φ6.0 in diameter compatibility. With a variety of models available for both domestic and international sales, we are dedicated to providing custom-fit solutions for our customers.

Machinery development using the machining know-how of HI-TAK, experts in deep hole processing

- Drill breakage detection function to prevent breakage of gun drills

We achieve drill breakage prevention and visualize replacement time by constantly monitoring the torque of the main axle built-in spindle motor. Prevents cutting defects caused by cutting edge wear and reduces the rate of defective products.

- Low oscillation, high-performance hollow built-in spindle motor

-2.2kw built-in servo motor

-0.75kw built-in motor

-servo spindle motor (1.5kw, 7kw, etc.)

- Flexible chucking technology

Can be exchanged freely between chucks, including a collet chuck or a scroll chuck, depending on its work shape

- Highly durable chip box optimized to hole size

Maximizes the effective length of the gun drill to achieve increased machining accuracy and stability.

JDH-600-RF

Medical gun drilling machine

Relative rotational type of Precision gun drilling machine

JDH-300-R

Relative rotational type of deep hole boring machine

Sample products