Description

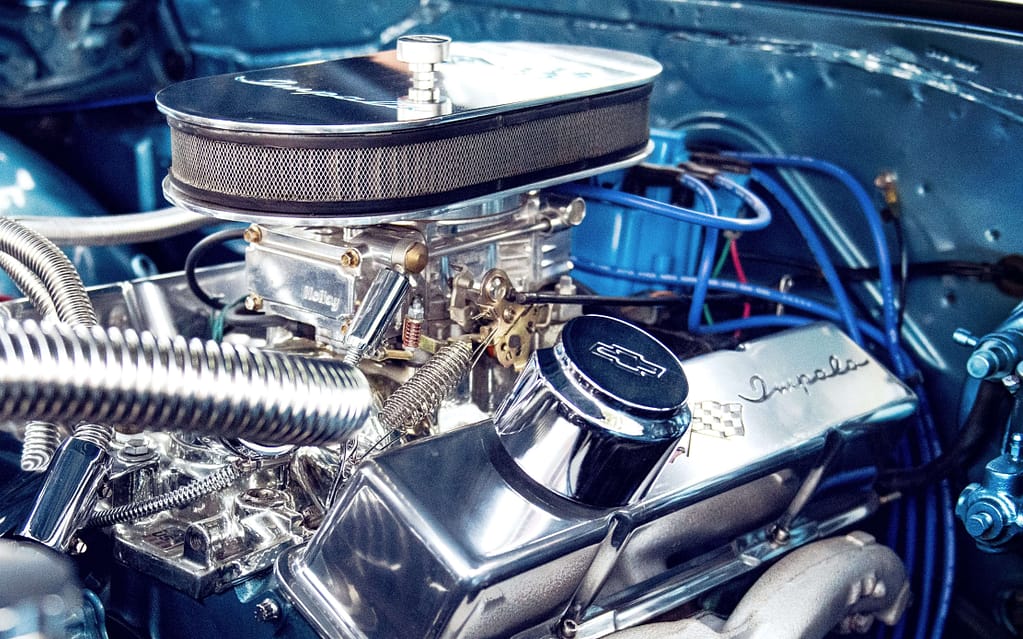

Automotive manufacturers use gun drilling machines to achieve high productivity and accuracy. These systems are often highly reliable and paired with automated solutions. Gun drilling is a cost-effective production method used to make numerous holes in parts such as transmission shafts, engine blocks, airbag chambers, camshafts, and other internal engine components. Therefore, efficient tools are crucial in the production line of automobile parts to increase profitability. Deep hole drilling by gun drill is an important material removal process in industries such as automotive, molding, and turbines and is expected to increase in complexity and demand in the future.

Automotive parts

- Mold (core pin for cooling water)

- Shaft-related (hollow hole)

- Piston connecting rod (lubrication hole)

- Fuel injection nozzle related (lower body)

- Common rail,

- Input shaft (AT)

Products detail data – by our gun drilling machine

–

- Core Pin φ2 depth 450mm φ1.5~15 depth 500mm

- Sleeve pinφ3~15 depth 300mm