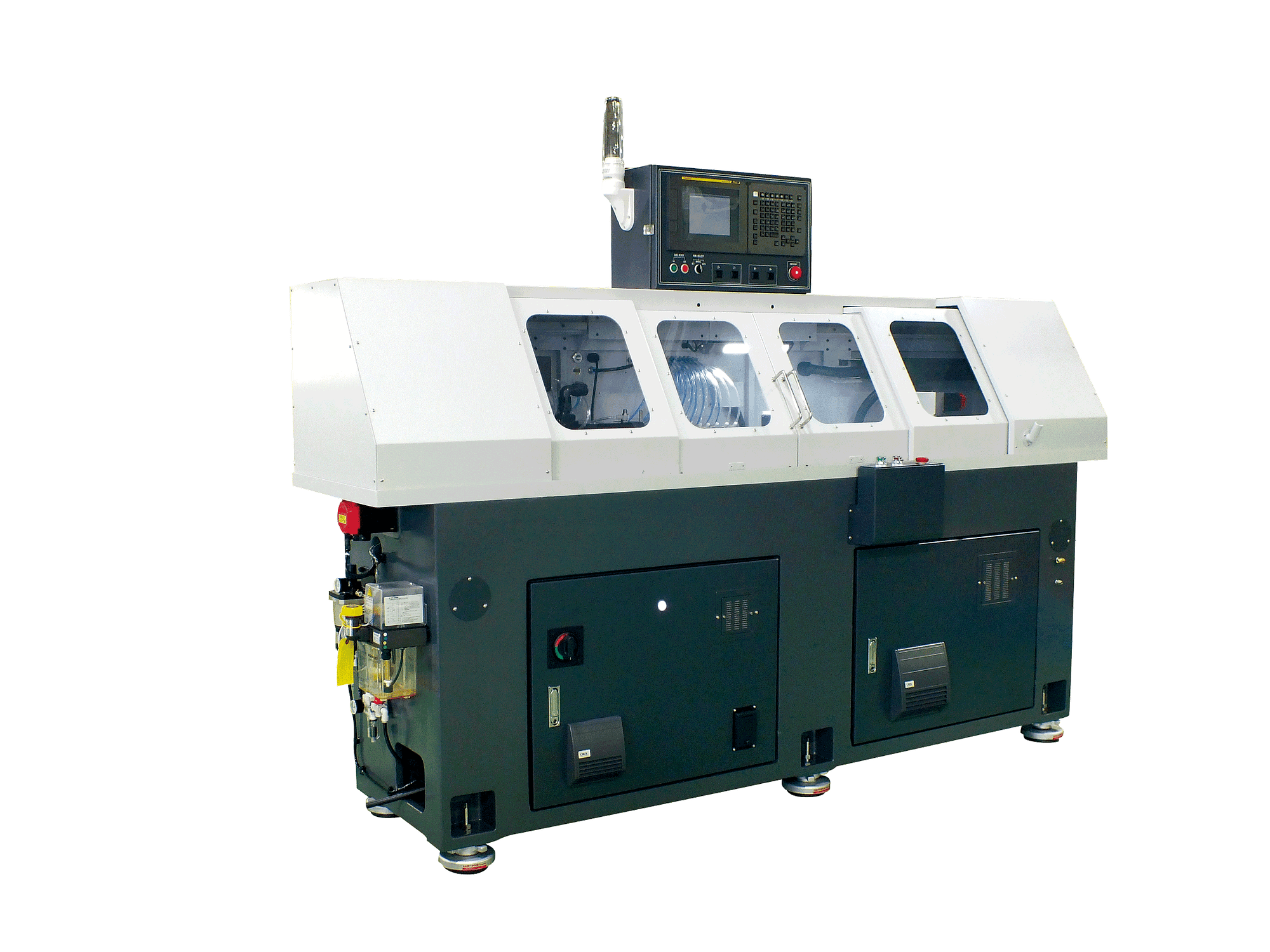

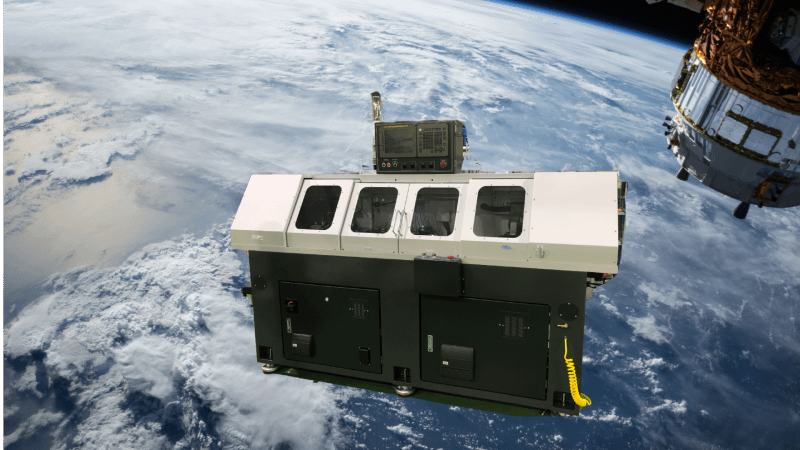

We are a leading precision gun drill machine manufacturers for small diameter gun drills from Φ0.5 to 30. The product sales overseas, and contracted processing services in Japan for 30 years.

Our deep hole drilling is based on over 30 years of experience as specialists in deep hole drilling.

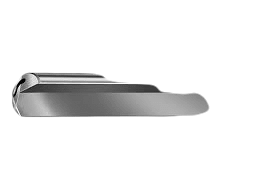

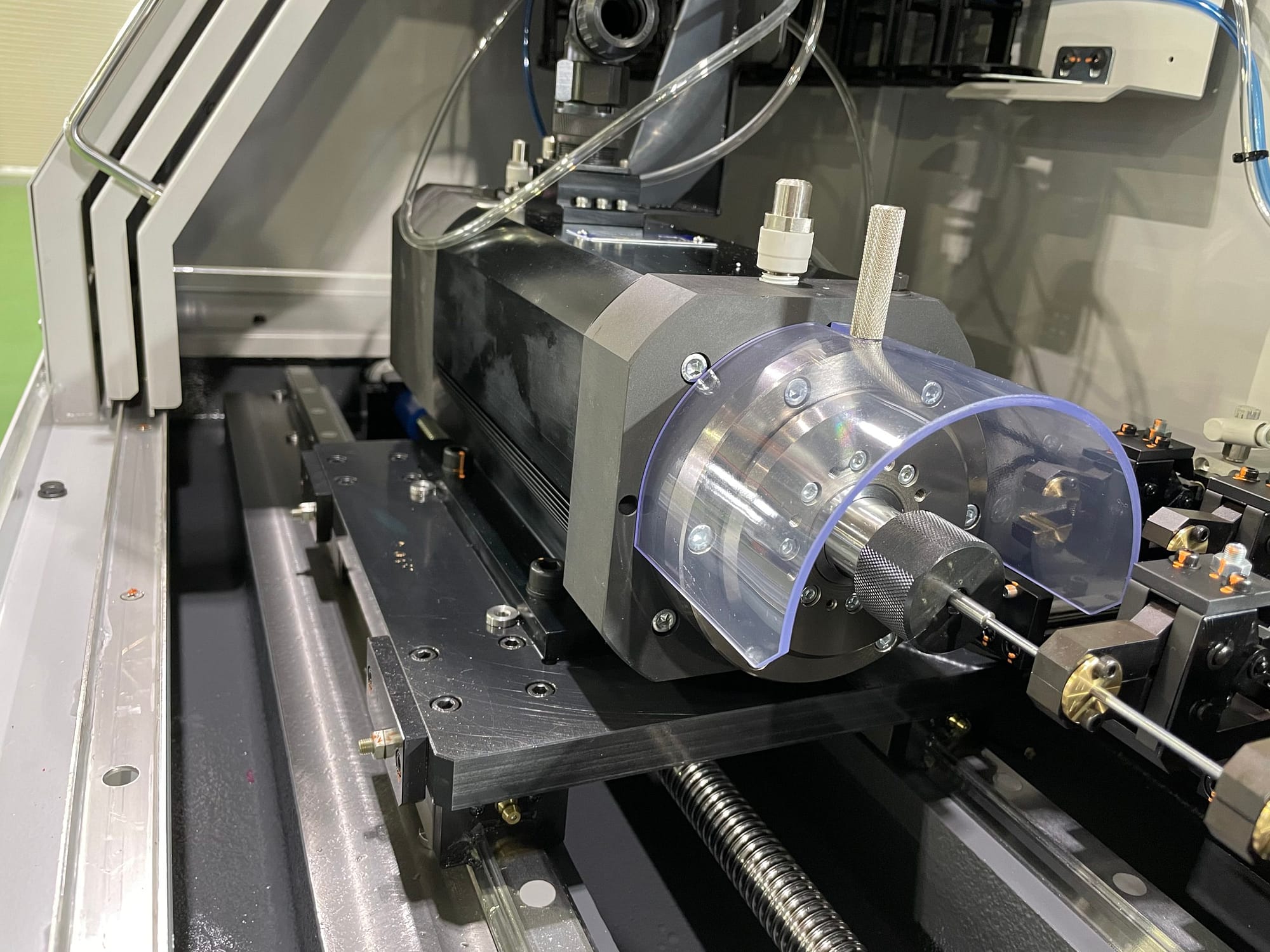

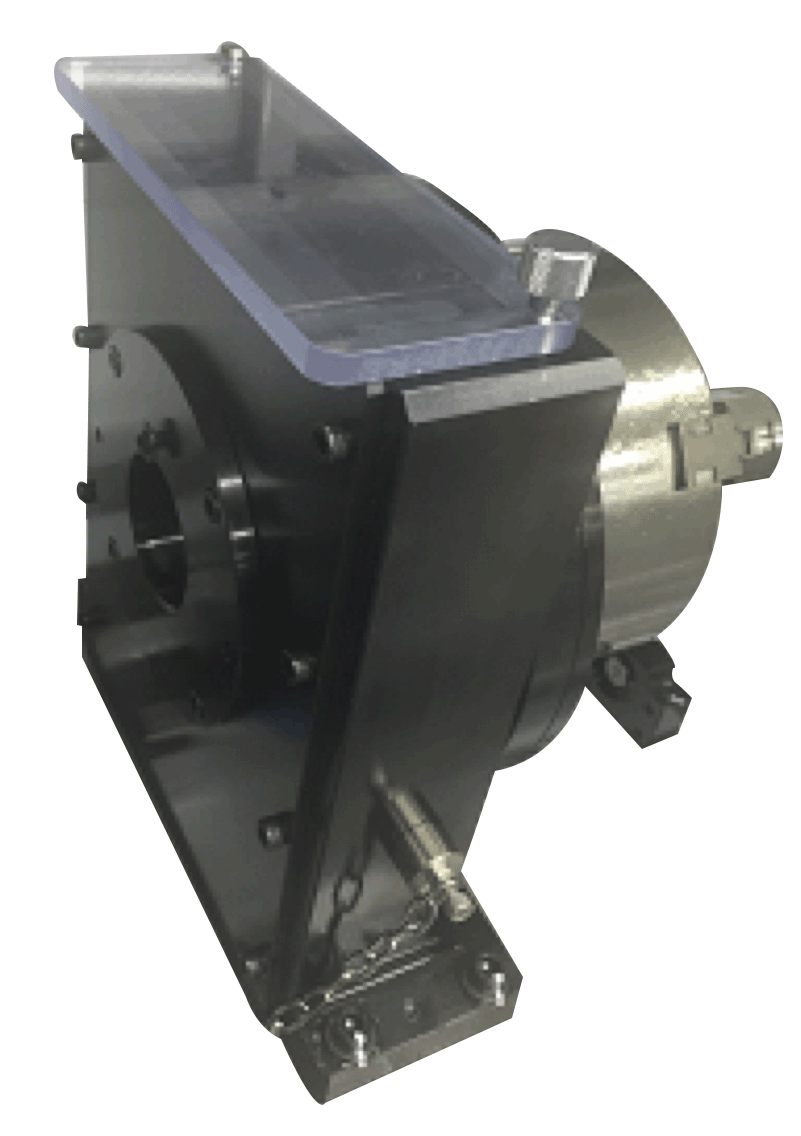

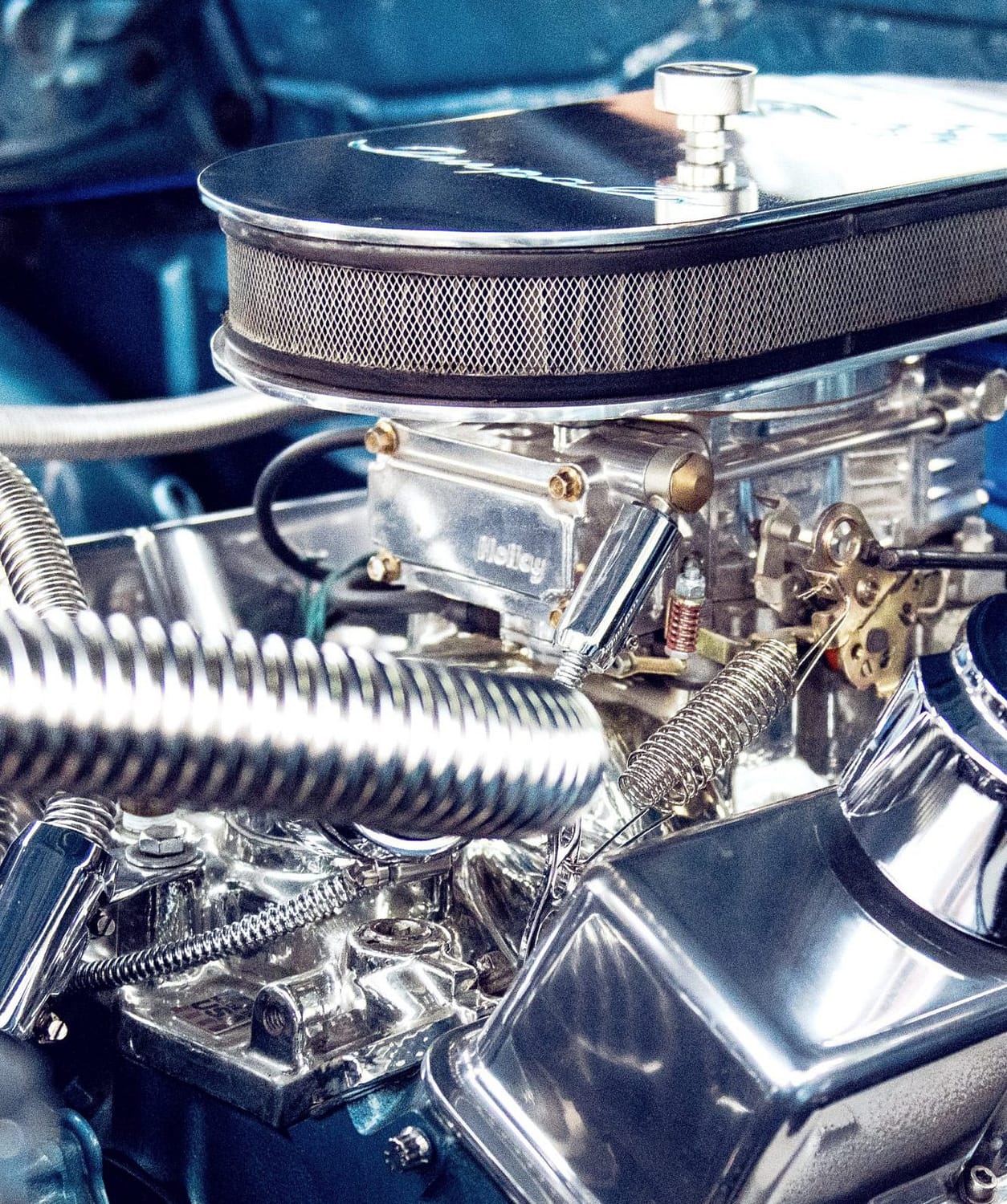

chucking technology

Can be exchanged freely

between chucks, including

a collet chuck or a scroll

chuck, to suit the work shape.

hollow built-in spindle motor

・2.2kw built-in servo motor

・0.75kw built-in motor

・servo spindle motor (1.5kw, 7kw, etc.)

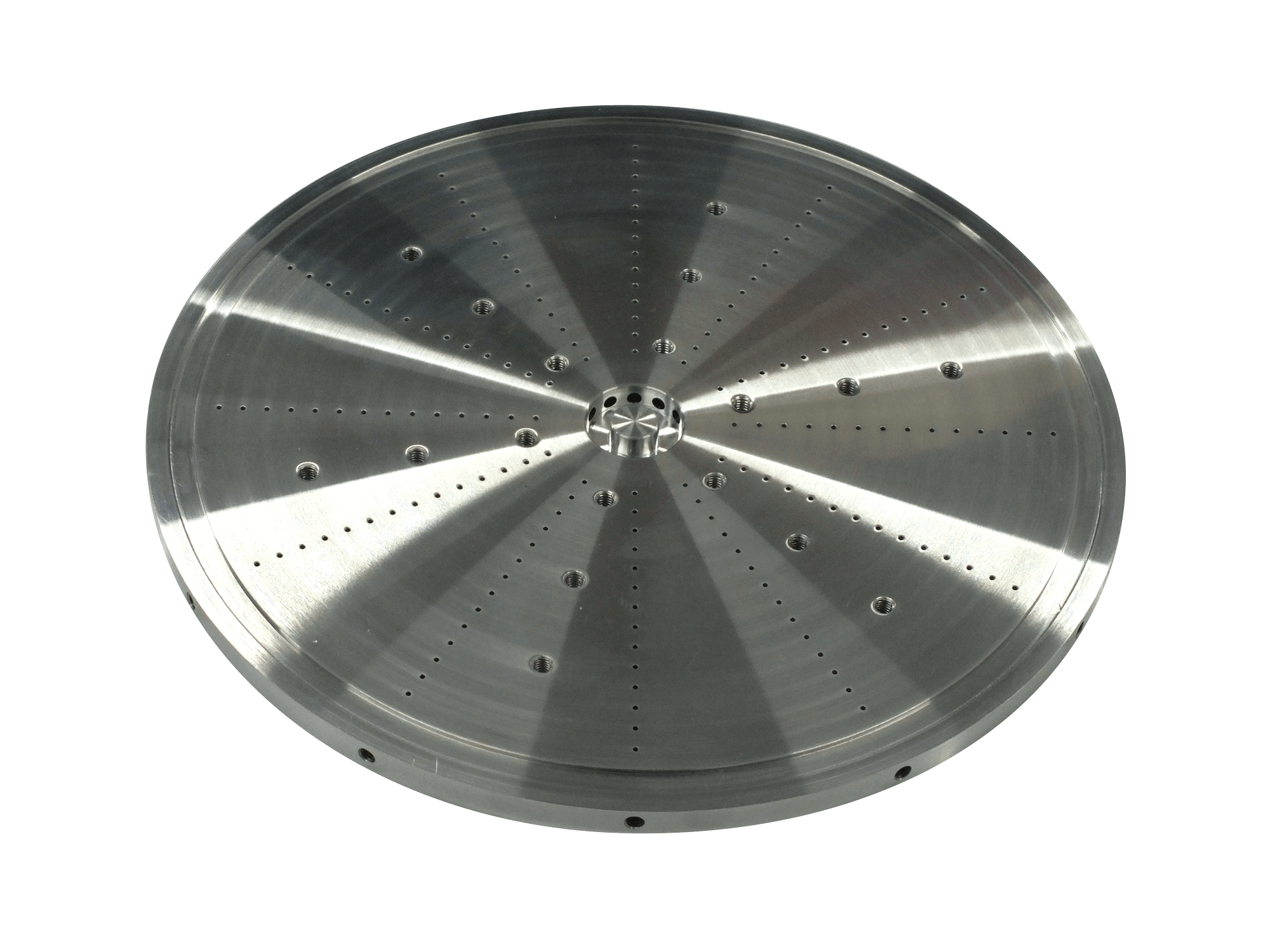

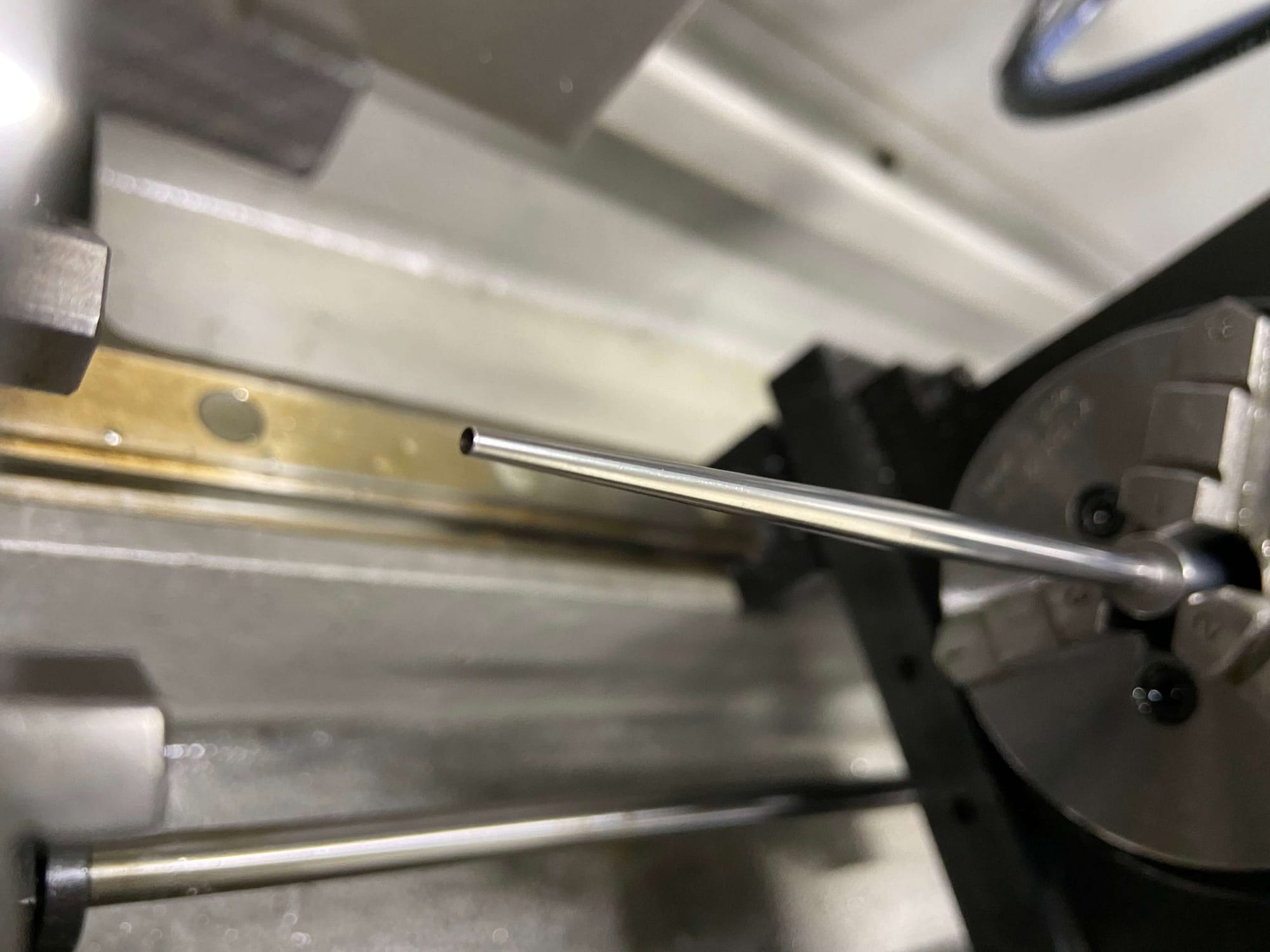

optimized to hole size

Maximizes the effective length

of the gun drill to achieve

increased machining accuracy

and stability.

withgun drilling machines manufactured by HI-TAK!

Feel free to consult us with any concerns you may have regarding deep hole machining. We have the processing know-how to cultivated through contracted machining.

By installing the FANUCʼ s CNC system, customers are provided world-class operability and in applicable countries you can receive FANUC services within 24 hours.

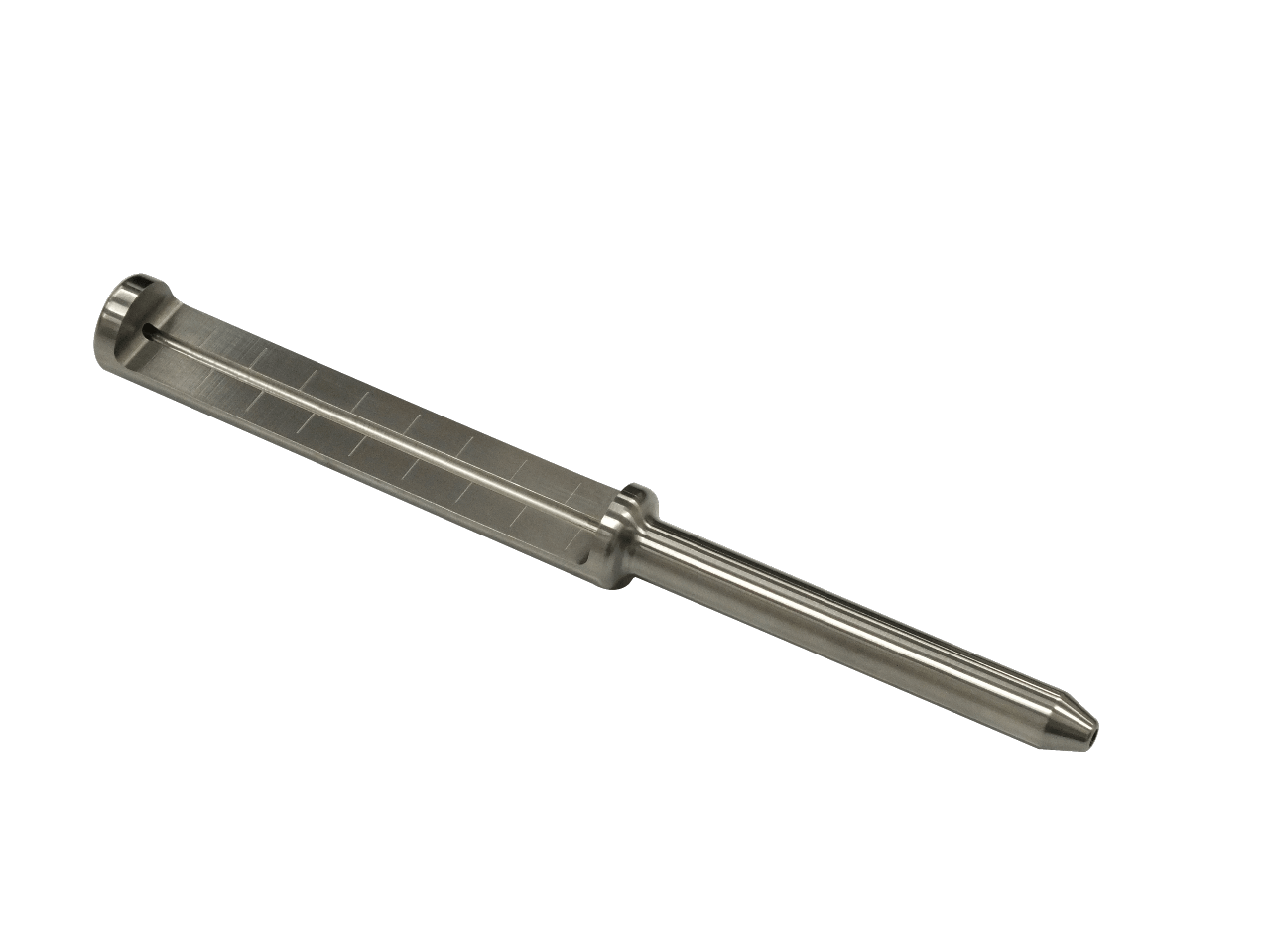

detection function】

Drill breakage prevention and

the visualization of replacement

timing are achieved by continuously monitoring built-in motor torque of the main axle. Helps reduce nonconforming product rates by preventing drill failure caused by tip wear.

of deep hole drilling experience

We have worked with more than 60 companies on contract machining related in the field of medical care, and we have a track record of machining for other applications. Our deep hole drilling machines enable deep hole drilling for a variety of parts.